Deskside Chats: Universal Joints (Video)

Bearing manufacturers have a number of skilled engineers on staff – along with people who have been in the industry for decades. One of the great things about having these folks as coworkers is the way that they are able to explain complex concepts.

Lip or Boot: Universal Joint Seal Selection

Grease is what keeps moving parts in motion. Traditionally, u-joints are outfitted with lip seals to help retain the grease. The lip seal also allows for regreasing and usually acts as a barrier to prevent contaminants like dirt and moisture from getting into the unit.

Get Ready for a Fight: U-Joints vs. Square Ball

Wondering how the Square Ball Universal Joint compares to traditional ujoints? This side-by-side comparison walks though the differences between the two designs.

Fidget Spinners Highlight Ball Bearings

They are a hot seller – if you can find them in stock. Fidget spinners are lauded for improving concentration and reducing stress, along with calming some of the anxiety associated with autism. But what are they?

How does a sway Link bar differ from a sway link?

Sway bars and links are found in ATVs, forklifts, racing cars and family cars – basically any type of vehicle with a suspension. Maintaining a vehicle in an upright position during a turn is vital to safety. The parts within a suspension system that help to control this movement are the sway bars and sway links. …

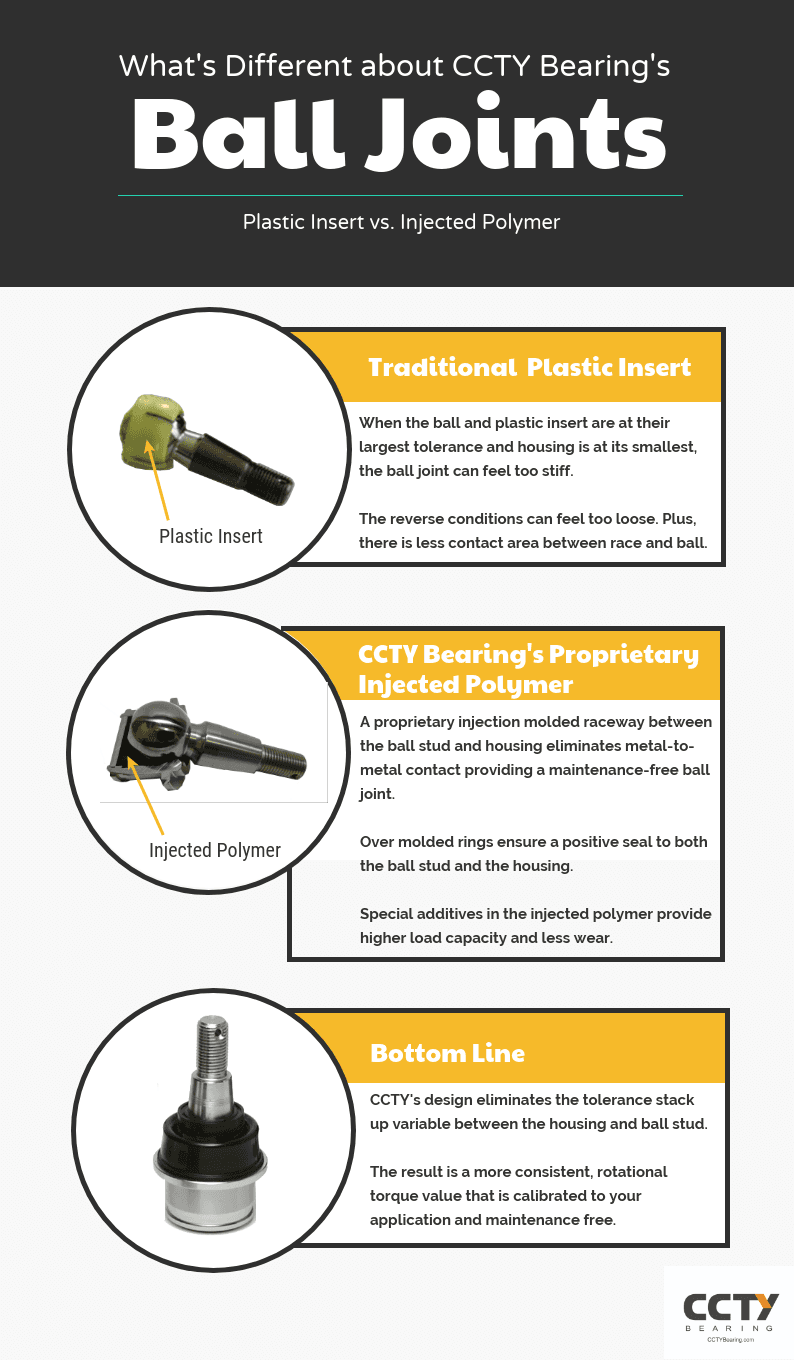

Tolerance Stack Up in Ball Joints

Ever try to move a ball joint but it’s too stiff … or too loose? The wide range rotational torque values can be attributed to tolerance stack up.

Choosing the Correct Mounting for Your PTFE Bushing Design

Finding the proper bushing is important, but it’s not the only thing to consider when developing the best bearing system. Correct mounting is just as vital in order to allow the busing to properly function and for maximum efficiency.

How Proper Lubrication Impacts Agricultural Equipment

Tractors and combines, along with hay balers and harvesters, have many moving parts that are made possible with bearings and ball joints. To maintain these heavy-duty machines under optimal performance conditions, special attention to bearing lubrication is necessary.