Ever try to move a ball joint but it’s too stiff … or too loose? The wide range rotational torque values can be attributed to tolerance stack up.

Ball Joints Deconstructed

A typical ball joint is comprised of:

- the ball stud

- housing

- housing cap

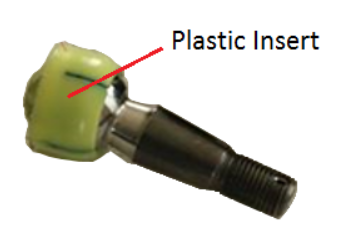

- a polymer raceway – either a separate insert or injection molded

- seal

What is Tolerance Stack Up?

Ball joints made with the same materials, machines, processes and people will have different rotational torque values. It’s impossible for components to be perfectly manufactured to an exact dimension every time. Therefore, a tolerance range is specified. However, since each component has a range, more variables enter into the equation with each added component. The end result is the tolerance stack up.

When the ball and plastic insert are at their largest tolerance and housing is at its smallest, the ball joint can feel too stiff. The reverse conditions can feel too loose.

Benefits of Injection Molding

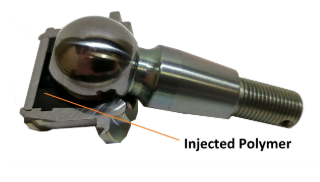

Injection molding nullifies the tolerance stack up variable between the housing and ball stud. The result is a more consistent, rotational torque value. A propriety resin is injected into the housing assuming the shape of the housing and ball.

Similar to the plastic insert, molding prevents metal-on-metal contact. However it also provides two additional benefits:

- More surface area contact that reduces overall surface MPA stress load on the bearing surface.

- Design specific grease storage areas above and below the ball to ensure quite operation for the life of the joint.

What to Look for in a Ball Joint Manufacturer

Managing tolerance stack up is a function of a company’s engineering and equipment capabilities. Tolerance ranges are dependent on the ball joint manufacturer’s capabilities. This is where bearing manufacturers have a clear advantage. By the nature of precise machining requirements for bearing production, bearing manufacturers excel at managing tolerance stack up due to machine and production standards that are designed to be extremely accurate.

In-house injection molding allows for heightened control over the process and quality. If a ball joint manufacturer subcontracts this aspect of production, they lose a level of managing overall product consistency.

Finally, a manufacturer should be able to offer a variety of polymer formulas to meet specific application requirements. For example, snowmobiles and construction equipment should use an injection compound that has been tested to perform at 40 degrees below zero while maintaining the ball joint’s ability to fully function.

The Bottom Line

Ball joints play a vital role in their applications. When a consistent rotational torque range is required, injected molded polymer has clear advantages over plastic inserts.