Wrapped bushings – or bushes – have been around for decades. Their simplicity, efficiency and ability to take up space or protect the shaft are a testament to their versatility and long standing success. Aside from the materials used to form the bushing some with self-lubricating features, one of the questions that is frequently asked relate to the joint construction of the split along the bushing.

Why do bushings have splits?

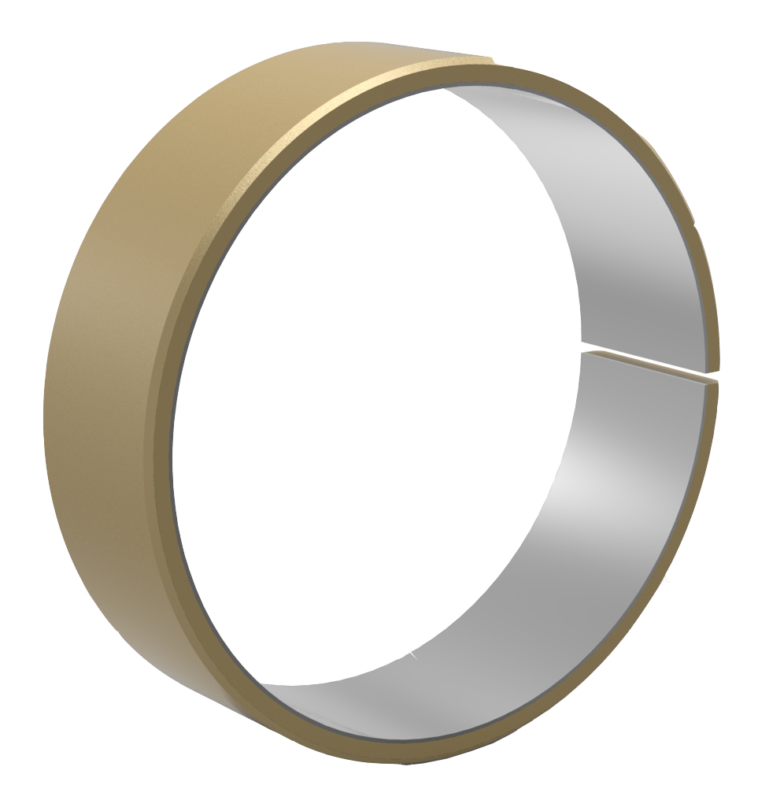

When a wrapped bushing is formed, a rectangular blank of metal is cut from the process coil and rolled into a cylinder shape. The split occurs where the two blank edges meet to form the bushing cylinder shape.

Split bushings have three main advantages over a solid ring construction:

- More economical for the manufacturer to produce

- Lower purchase cost

- Sustaining a self-lubricating benefit offering a grease-free solution

Types of Split Joints

There are two common types and options of split bushing joints:

- Straight Joint, also known as a Normal Joint

- Clinch Butt Joint

Straight Joint

Pros: Affordable, versatile, and most common in practice use

Cons: Even though straight joints are a common style in the industry, they can also add difficulty during transit, handling and assembly due to the potential for bushings to become entangled. If the gap is too large, it will increase the size of the chamfer making it difficult to press fit, and potentially resulting in higher rates of scrap.

Clinch Butt Joint

The clinch butt joint contains a straight line connection with half-moon or puzzle piece cuts. This sophisticated design acts to integrate a key-to-lock benefit to join the split together. It closely maintains the similar integrity of a solid ring style but brings in the economy of a split joint.

Pros: Easier for the end user to handle than a normal split. The smaller chamfer reduces assembly issues.

It allows the bushing to work better in high load or performance related applications, such as engine bearings, pumps, etc. The clinch butt joint can be applied to thinner wall bushings so that the cylinder integrity does not become compromised during normal press assembly. And, no interlocking potential of neighboring parts since there is no open gap on the seam.

Cons: Greater production difficulty and tooling costs due to the intricate design and metal forming. In most cases they are considered custom or special parts.

Bottom Line

As manufacturing becomes more automated, splits are evolving. Each split has unique features that should be considered based on the bushing’s wall thickness and application, along with cost factors.